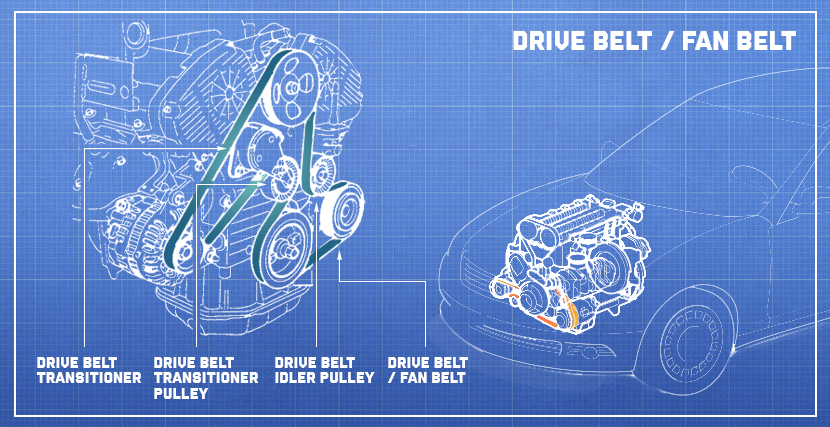

Drive Belt/Fan Belt

A faulty drive belt is the root of many engine troubles. Let’s check the list of the most common signs of a failing drive belt.

Abnormal or squealing noise

A drive belt can stretch over time, causing an annoying squealing noise. This happens due to its slipping on the drive pulleys. The sound is especially noticeable when your engine is cold and you have just started it.

Your drive belt is damaged or cracked

Inspect your belt. If it is cracked or broken, or shows any other signs of damage, you should replace the drive belt as soon as possible.

Warning lights come on

Your drive belt operates a lot of engine devices. One of them is your alternator. Since a slipping or broken drive belt cannot drive the alternator’s pulley as it should, it will not be able to generate enough voltage to operate the vehicle’s systems and devices. If your car or truck features a lot of voltage-depending devices, like most vehicles produced 10 or 20 years ago, your onboard computer will turn on the warning lights.

Your battery is run down

Your vehicle’s battery accumulates energy needed to start the engine and power some devices when the motor is not running. It needs to be recharged on a regular basis to provide enough power for the next engine start, which is the job of the alternator. If the alternator is not able to generate enough power due to a faulty drive belt, the battery will slowly go dead.

The steering wheel is hard to turn

If your drive belt runs a hydraulic steering pump, the failure of the belt will cause problems with your steering assist.

Your engine runs too hot

Your water pump is driven by a drive belt. A slipping or damaged drive belt will not make the water pump run at its normal speed, so the coolant will not properly circulate through the engine and the radiator, resulting in the engine overheating. In this case you should shut down the engine and get in touch with your mechanic for repairs.

How does a drive belt work?

The majority of your engine’s devices are operated by a drive belt that is sometimes called a fan belt. Running the gamut from the alternator, water pump and power steering pump to the A/C compressor, all of them are powered by the drive belt.

Every belt-driven engine accessory comes with a pulley wrapped by the belt. The engine’s crankshaft also has a pulley which is the source of power for the belt, causing it to move. The crankshaft’s pulley drives the belt which in turn runs the devices’ pulleys.

Types of drive belts

There are two main types of drive belts including v-belts and serpentine belts.

V-belt

This type of drive belt is called so because of its shape. Being wide on the top, it goes narrower to the bottom, forming a v-shape. V-belts are common for older vehicles and are widely used to drive an alternator and some other accessories. First v-belts, called fan belts, were the only belts used in vehicles. Old vehicles usually came equipped with one v-belt that drove all accessories.

As time passed, automakers began to add more and more accessories to the engine, so a single v-belt could not handle all of them. To solve this issue, they began to equip engines with several v-belts, each of which drove one or two accessories, for example, the steering pump and alternator.

Depending on the devices they drive, some v-belts feature grooves on one side, while the others are completely smooth. In most cases, ribbed v-belts are more flexible and generate less heat compared to their smooth counterparts. Anyway, both of them are easy to adjust with a manual pivot tensioner.

Serpentine belt

A serpentine belt is a longer version of a drive belt. This type of drive belts can be found in just about any modern vehicle. As a general rule, only one serpentine belt is used to drive all engine accessories. Similar to v-belts, serpentine belts may also have grooves on one or both sides, however, they are not adjustable like the old-school belts. At the same time, serpentine belts usually last longer and their inability to adjust is compensated by automatic tensioners.

Can I fix a bad drive belt?

If it is a v-belt and it’s not broken or cracked, you can try to adjust it. On cars equipped with a serpentine belt, replacing the automatic tensioner may fix the problem if the belt is not damaged.

A broken, cracked or worn-out belt should be replaced regardless of its type. Replacing a v-belt is usually a simple task you should tackle yourself. However, serpentine belts drive a lot of accessories and may require special tools to be installed properly, so it’s better to hire a qualified mechanic.

A professional mechanic will not only replace a belt, but also inspect all pulleys and tensioners for damage. Some automatic belt tensioners come equipped with special indicators showing how much the belt is stretched, so this will also be checked by a good technician.

On a vehicle with a serpentine belt, a mechanic will need to loosen the tensioner, replace the belt with a new one and then release the tensioner. Besides, he should check whether the belt is properly routed and start the engine to double check its operation.