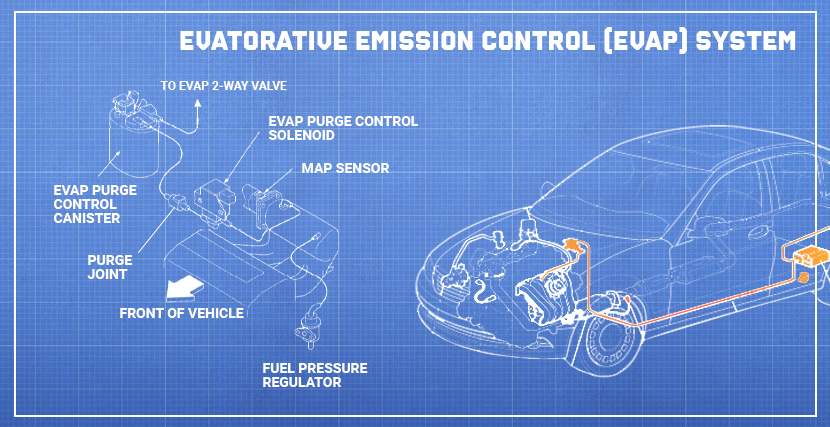

Evaporative Emission Control (EVAP) System

An evaporative emission control system or an EVAP system does exactly what its name suggests, preventing harmful fuel vapors from escaping the fuel system by absorbing them when the vehicle is not running and redirecting them to the engine when it is in use.

Your engine control unit continually monitors EVAP system operation. If it detects any problem related to its operation, the computer will turn on the check engine light to alert of the issue. If this happens, the first thing that needs to be checked is your gas cap since a loose gas cap is the most common trigger that causes an illuminated check engine light. The other triggers can be a system leak or a failed EVAP system component. Whichever the problem, it should be addressed by a professional mechanic, who will read stored trouble codes and look up the OBD-II code.

Your EVAP system consists of many components, including the fuel tank, charcoal canister, canister purge and vent valves, and many others. Let’s describe some of them.

Fuel tank

This is a plastic container where the fuel needed to power the engine is stored. It features a special float that sends signals to the fuel gauge or the engine control unit. In most cases, the tank also houses a fuel pump assembly with a fuel filter and a fuel pressure regulator.

Charcoal canister

A charcoal canister is a plastic box with activated charcoal inside the box, which absorbs fuel vapors when the engine is not running. It also redirects some fuel vapors to the intake manifold via a purge valve when you’re driving.

Canister purge valve

This is a one-way computer control valve (solenoid) that allows for recycling fuel vapors to the intake manifold.

Canister vent valve

This valve serves to prevent outside air from entering the tank when testing the EVAP system. It also allows for proper tank ventilation when refueling it.